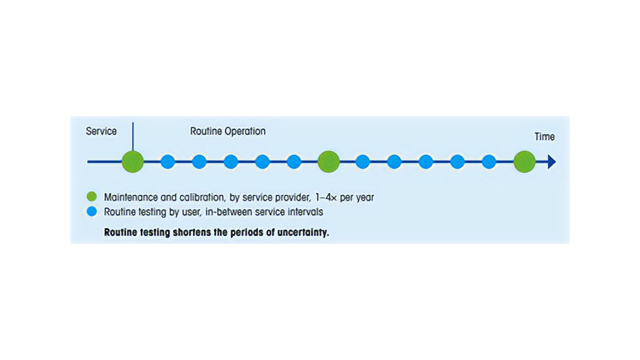

Quality standards and guidelines, such as ISO 8655, ISO 17025, Good Laboratory Practice (GLP), and Good Manufacturing Practice (GMP), require regular calibration and/or verification of measuring instruments at specified intervals. This monitoring, calibration, control, and routine testing of instruments is intended to ensure metrological traceability and provide evidence of the pipette’s “fitness for purpose.”

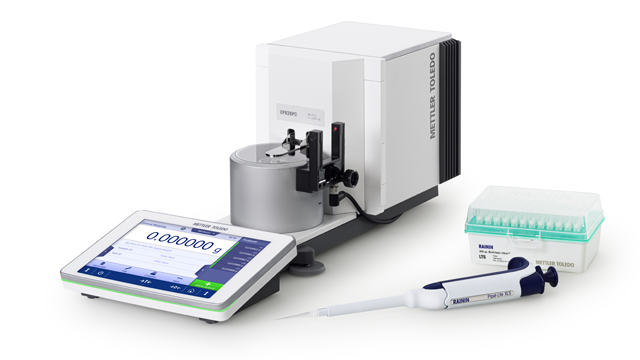

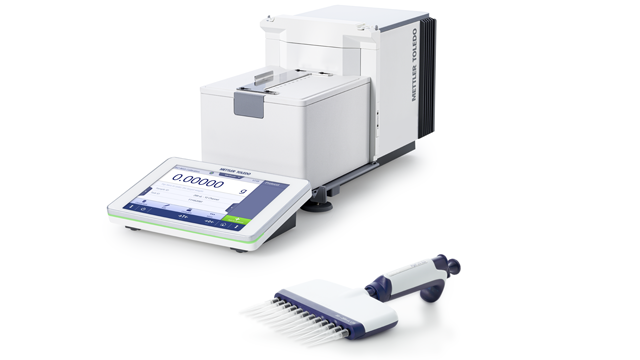

METTLER TOLEDO’s Good Pipetting Practice™ (GPP™) program includes quality assurance measures for pipettes and simple, straightforward recommendations for their selection, installation, calibration, and operation. It provides a comprehensive, systematic approach to maximizing pipetting accuracy and reproducibility.

A combination of three complementary activities ensures that your pipette delivers reliable results every day:

- Pipette calibration and preventive maintenance – performed by a service provider

- Pipette routine testing – performed by the user

- Pipetting user training – delivered by a pipetting expert

Routine testing (also referred to as a pipette test, performance test, or quick check) provides reassurance that a pipette continuously delivers accurate and reliable volumes between calibrations. Compared to calibration, routine testing provides additional security because it checks the system of “user and pipette” under daily laboratory conditions, mimicking the actual pipetting process. This is particularly important for critical applications because the user technique can be a dominant source of pipetting uncertainty.