Clear AllView Results ()

Filter ()

Add 1 or 2 more products to compare

Explore our Services

We support and service your METTLER TOLEDO Product Inspection equipment through its entire lifecycle, from installation to preventive maintenance and calibration to equipment repair.

Uptime. Support & Repair

Compliance. Calibration & Quality

Expertise. Training & Consulting

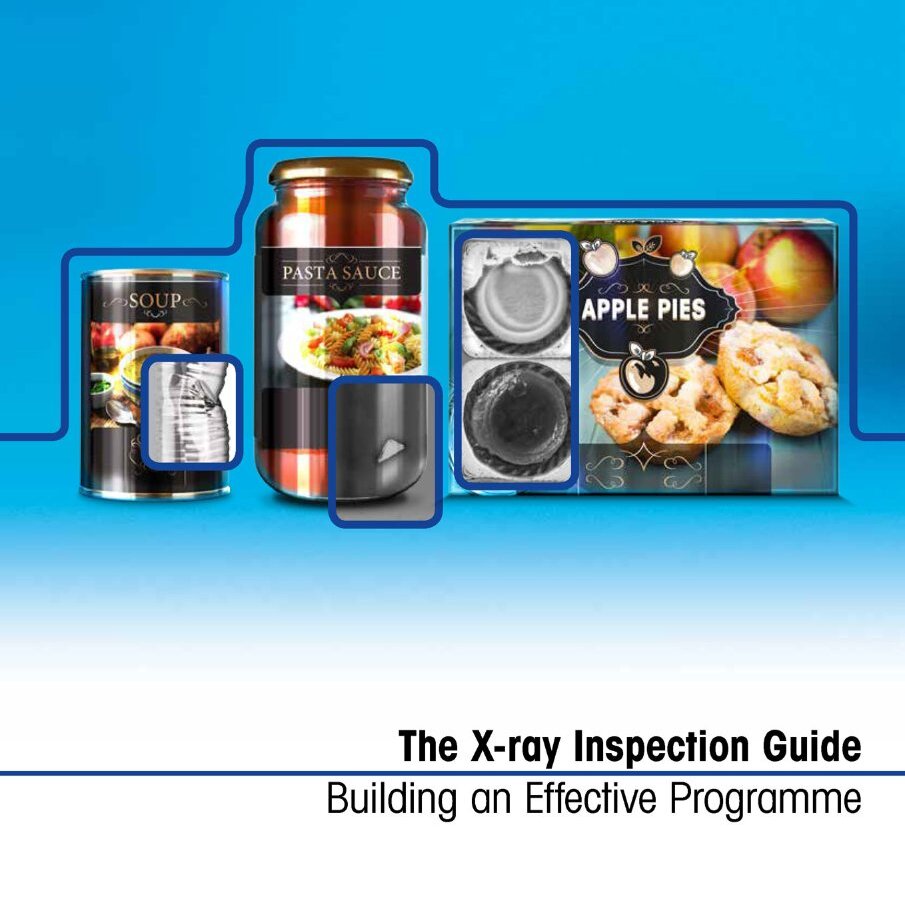

- Automated X-ray Inspection Systems

- Blister Pack Product Inspection

- Chicken Bone X-ray Inspection Systems

- Conveyor Belt X-ray Machines

- Electronic X-ray Inspection

- Foreign Object Detection in Meat Processing

- Industrial X-ray Inspection Systems

- Pharmaceutical X-ray Inspection Systems

- Safeline X-ray Dual Energy Technology

- The X2 X-ray Inspection Series

- The X6 X-ray Inspection Series

- X-ray for Contamination Detection

- X-ray Inspection for Baked Goods

- X-ray Inspection for Dairy Production

- X-ray Inspection for Pet Food

- X-ray Inspection Systems for Glass Jars

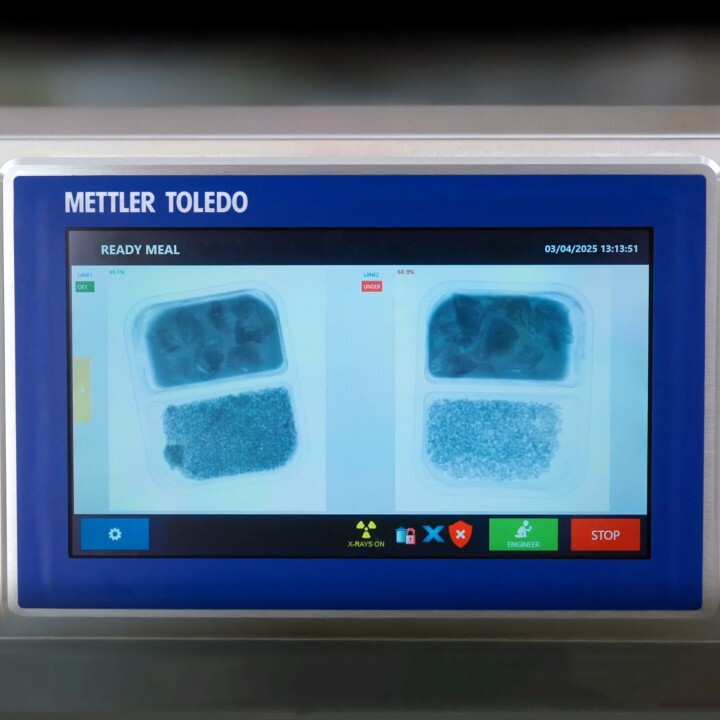

- X-ray Inspection Systems for Ready Meals

- X-ray Machines for the Food Industry