From Wafer to Water: How Does TOC Impact Semiconductor Quality?

Effective TOC control involves multiple purification stages: reverse osmosis, micro-filtration, ion exchange, adsorption, and UV photo-oxidation.

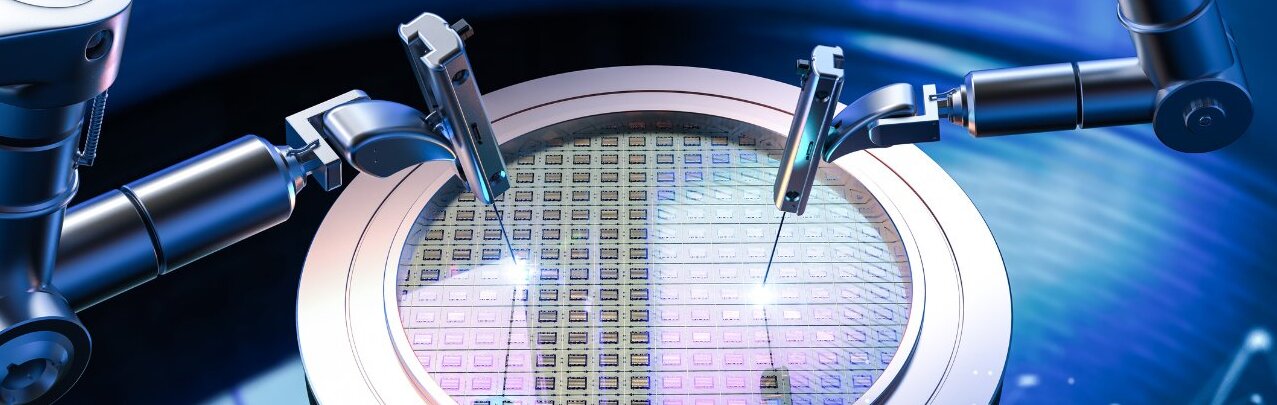

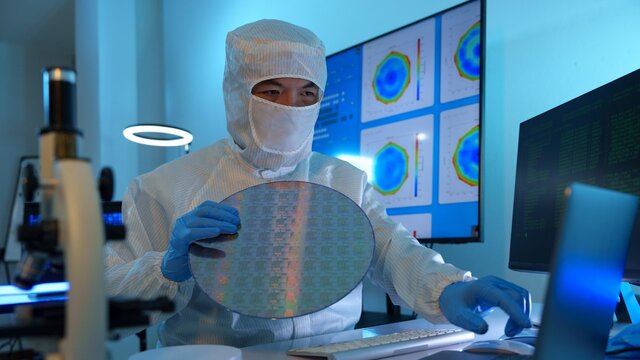

Continuous TOC monitoring throughout the water treatment and distribution system promptly identifies quality issues before they affect production, enabling rapid corrective actions. Therefore, in addition to the water system itself, TOC monitoring is vital during semiconductor manufacturing steps where UPW contacts wafers and chemicals.

.png/_jcr_content/renditions/cq5dam.web.1280.1280.png)