|

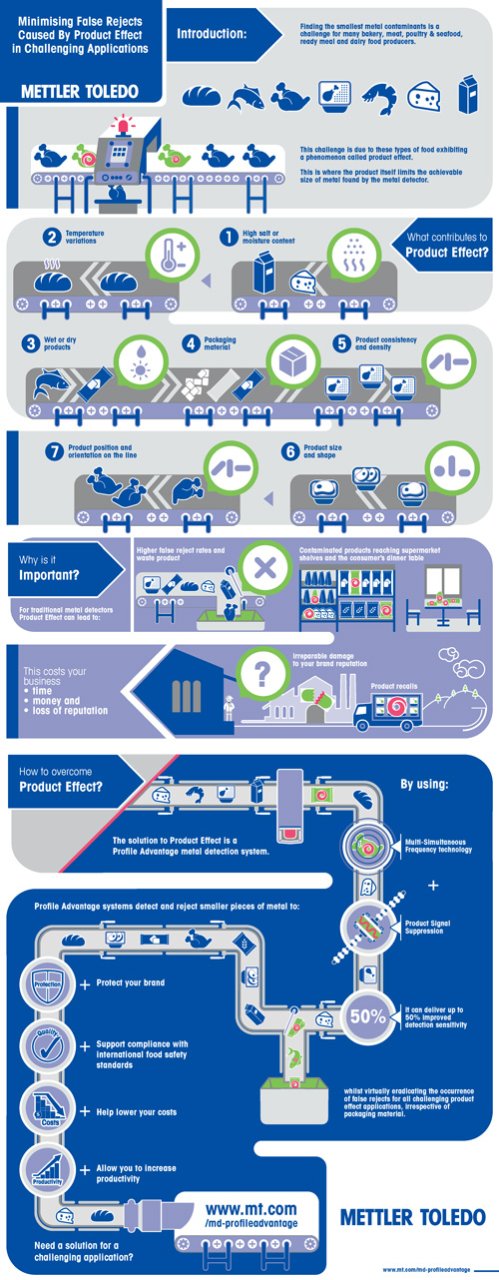

Overcoming product effect is a common challenge for many food manufacturers. Product effect can impact companies that produce meat, poultry, seafood, dairy products, baked goods, ready meals, or products packed in metallized film.

In metal detection, product effect occurs when the product being inspected has characteristics that behave like metal. Properties such as high water content, salt levels, or elevated product temperature can cause the metal detector to produce false rejects.

Traditionally, manufacturers reduce metal detector sensitivity to address product effect. However, this approach increases the risk of missing larger metal contaminants.

METTLER TOLEDO offers metal detection solutions that help overcome product effect. Our technology can detect smaller metal contaminants in wet or warm products to minimize false rejects and product waste.

Download our infographic to learn more about:

- What is product effect?

- Seven key factors that contribute to product effect in metal detection

- The importance of overcoming product effect

- How advanced metal detection technology can minimize product effect

- The benefits for food manufacturers

With current metal detection technology, bubbles and voids in product flow do not affect performance. Overcoming product effect is now possible in many food processing applications, not only those using conveyors.

Learn how to solve product effect challenges, improve productivity, and protect your brand in the food industry. Download our infographic today!