Hydrogenation is a process widely used in the chemical industry to add hydrogen to unsaturated organic compounds, with the aim of producing saturated compounds. Chemical engineers are heavily involved in the design and optimization of hydrogenation processes, which play a vital role in various industries, including food and fuel production.

In the food industry, hydrogenation is commonly used to produce solid fats from liquid oils, such as margarine and shortening. By hydrogenating vegetable oils, their stability, functional properties, and overall quality can be improved. Similarly, in fuel production, the hydrogenation of unsaturated hydrocarbons in crude oil can produce more stable and less reactive compounds.

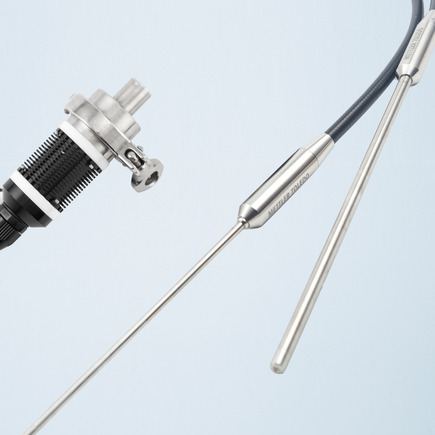

As a crucial part of the hydrogenation process, chemical engineers must select appropriate catalysts, design reactors, and process conditions to optimize conversion and selectivity, and manage safety considerations associated with high-pressure hydrogenation reactions. Additionally, they must strive to develop sustainable and environmentally friendly hydrogenation processes that minimize waste and energy consumption.