Wei, B., Sharland, J. C., Lin, P., Wilkerson-Hill, S. M., Fullilove, F. A., McKinnon, S., Blackmond, D. G., & Davies, H. M. L. (2019). In Situ Kinetic Studies of Rh(II)-Catalyzed Asymmetric Cyclopropanation with Low Catalyst Loadings. ACS Catalysis, 10(2), 1161–1170.

The authors point out the importance of dirhodium tetracarboxylates as catalysts for reactions with diazo compounds, in which the nitrogen is eliminated and transient metal carbene intermediates are formed. These catalysts have proven to be useful for a number of syntheses including enantioselective cyclopropanations. Due to the cost of rhodium and other factors, they were interested in investigating cyclopropanations using these rhodium catalysts at very low loadings. Specifically, they investigated cyclopropanation kinetics using a series of newly available chiral dirhodium catalysts in order to determine their relative performance at low catalyst loadings.

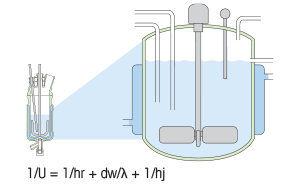

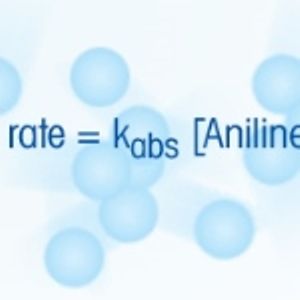

In-situ FTIR measurements using ReactIR technology proved to be an ideal means for investigating these reactions by tracking the rate of disappearance of the azide IR peak at 2103 cm-1. The kinetics of the cyclopropanations for a number of different catalysts were measured, but the researchers decided to further explore one of the catalysts with slower rates since it demonstrated the highest level of enantioselectivity. They found that reducing the catalyst loading from 0.0025 mol% to 0.001 mol% caused the enantioselectivity to decrease. In order to achieve high enantioselectivity at the lower catalyst loadings, a series of experiments was carried out with a variety of solvents and reaction conditions. They found that dimethyl carbonate proved to be a superior solvent for achieving both lower loadings and high enantioselectivity. The researchers applied this new information to the synthesis of an important intermediate in the synthesis of a hepatitis C drug, resulting in a 200-fold decrease in catalyst loading with even higher enantioselectivity.