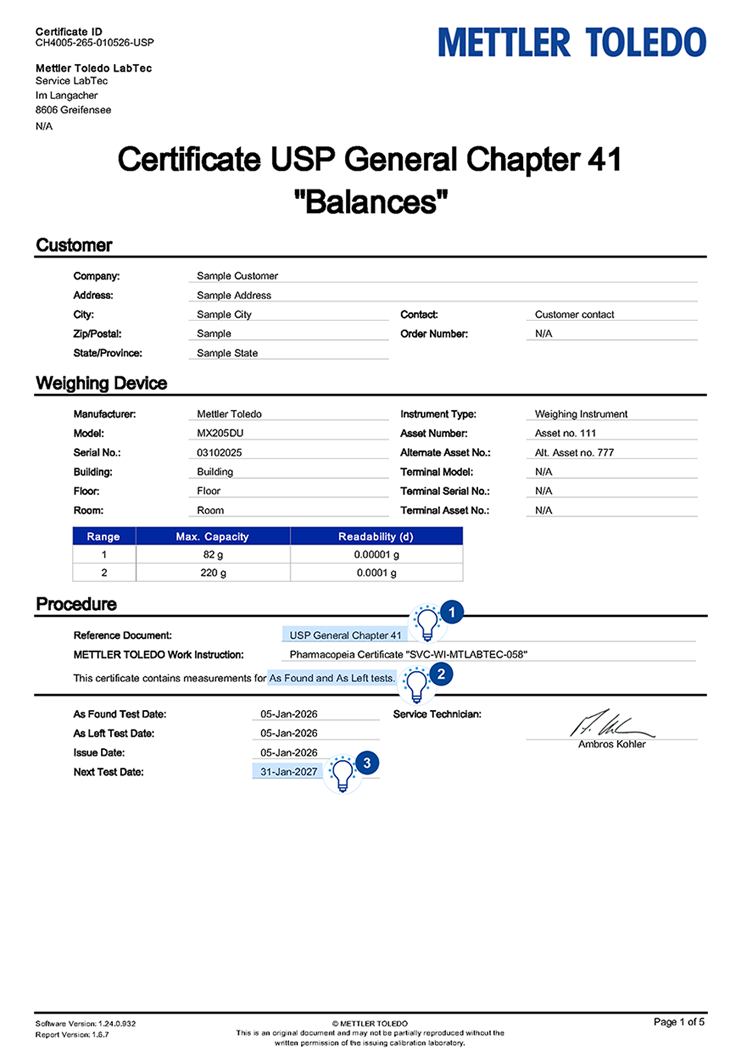

Page 1

1. Reference Document: This document refers to the applicable Pharmacopoeia, which in this case is United States Pharmacopeia (USP) General Chapter 41. Assessments for other relevant pharmacopeias are also available.

2. As-found and as-left: According to USP a calibration shall also be performed before and after any operation that could significantly alter the measurement performance of the balance (so called as-found and as-left calibration). As-found is important to determine if the validity of previous measurements of the user has been adversely affected. As-left takes into account any adjustments made during maintenance.

3. Next Test Date: Do you know what your recommended test frequency is? If you need help with defining your ideal calibration frequency, GWP Verification can help.