Interactive Product Animation

Our 360° product animation allows you to view the unique features in full detail.

The BBA639 and BBD659 industrial bench scales integrate easily into your weighing processes. With hygienic designs and intuitive operation, these scales optimize your checkweighing, counting, data integration, or quality assurance applications. Expedite scale assembly, adjustment, and approval with pre-configured indicator and platform pairings tailored to your needs.

Our 360° product animation allows you to view the unique features in full detail.

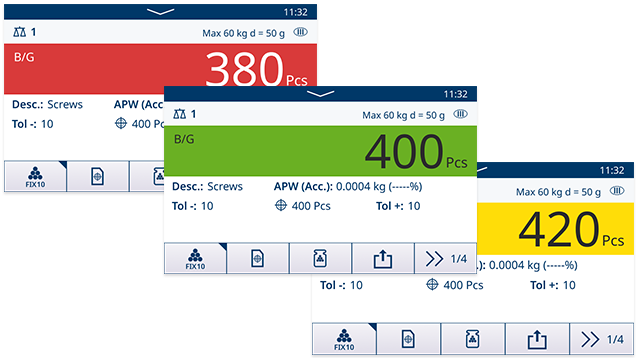

Speed up weighing processes and minimize waste with the simple three-color display system that confirms results at a glance:

When it comes to your weighing equipment, proactive planning for maintenance and service ensures optimum performance. METTLER TOLEDO Service delivers resources to enhance your efficiency, performance and productivity by providing service packages that fit your operational needs, maximize your equipment lifetime, and protect your weighing solution investment.

Find more benefits in the product brochures:

Access manuals and more:

METTLER TOLEDO BBA639 and BBD659 hygienic bench scales help you easily achieve higher sanitary standards and boost cleaning speed by up to 50% with no additional effort in any harsh or humid environment.

Hygienic bench scales are typically designed for areas that require strict hygiene standards, such as food production, pharmaceuticals, and chemical processing. These environments often involve harsh or corrosive conditions where cleanliness is crucial to prevent contamination and ensure product safety.

The digital BBD659 wet area scale from METTLER TOLEDO offers approved readability from 0.5 g to 200 g, depending on your weighing capacity.

METTLER TOLEDO also offers a variety of other digital or analog hygienic-area scales, so contact your local representative to find the best fit for your operation.

To maintain consistent product quality and comply with standards and regulations, the performance of scales needs to be verified at regular intervals. Periodic calibration by a service engineer combined with regular, scheduled testing by the user according to defined SOPs is the best way of maintaining accuracy, ensuring scales always perform within defined process tolerances. For support with defining a routine testing schedule, contact your local METTLER TOLEDO Service team.