Your Advantages With Our Solutions

Discover Our Analytical Balance Lines

Browse Through Analytical Balances

Didn’t Find a Matching Balance? Explore Our Other Balance Types:

Why METTLER TOLEDO Analytical Balances

Expertise

With over 80 years of weighing expertise, METTLER TOLEDO is a leader in precision measurements. Our exceptional metrological know-how, leadership in defining best practices, and reliable compliance knowledge set us apart. We are committed to innovation, consistently providing advanced technologies that establish new performance standards.

Highest Performance

Achieve continuous top performance in your laboratory measurements with METTLER TOLEDO.

Crafted from high-quality materials and rigorously tested for long-term reliability, our solutions offer superior accuracy and exceptional repeatability. Our durable devices ensure consistent results, reducing costly errors.

Seamless User Experience

We pride ourselves in providing an exceptional user experience through our continuous investment in advanced technologies.

Our products are intuitive and easy to use, allowing you to optimize productivity and streamline operations effortlessly. Every detail is meticulously crafted to create a cohesive and intuitive experience across all product families.

Digitalization and Automation

Transform your laboratory operations by leveraging centralized data management for improved traceability, enabling real-time monitoring to quickly identify discrepancies, and enhancing efficiency through automation to reduce labor costs while ensuring consistent quality.

Service

METTLER TOLEDO excels in service with a global presence, harmonized procedures, and a comprehensive service portfolio. Our team of over 1,500 certified service technicians is always ready to provide expert support. This ensures optimal performance of your equipment and extends its lifetime.

Sustainability

At METTLER TOLEDO, we prioritize sustainability and circularity in our balance design. Our robust and long-lasting products meet today’s needs while being prepared for the future. By using sustainable materials and practices, we minimize environmental impact and promote resource efficiency. Our commitment to circular design enhances product lifecycles, contributing to a more sustainable world.

Do You Want Your Balance to Perform at Its Best? Get It Serviced by the Market Leader

Do You Want Your Balance to Perform at Its Best? Get It Serviced by the Market Leader

FAQ

What is an analytical balance?

How does a typical analytical balance function?

How can I use an analytical balance?

How do I clean an analytical balance? How often should analytical balances be cleaned?

What is the difference between zero and tare?

Where are analytical balances used? What are the typical application areas of analytical balances?

How do I select the right analytical balance for my weighing application?

How can I manage data on an analytical balance?

How can I transfer my weighing results from analytical scale to a computer?

What is the difference between an analytical balance and a microbalance?

What is the difference between an analytical balance and an electronic balance?

Do I need to calibrate my analytical balance?

How should I calibrate my analytical balance?

What is scale measurement uncertainty?

How to avoid analytical balance weighing errors?

What is the uncertainty of an analytical balance?

What is the analytical balance's minimum weight?

What is the precision of an analytical balance, and what is the accuracy of an analytical balance? What is the difference and how can I test them?

What are the effects of static electricity on an analytical balance?

How can I eliminate static charges on analytical scale?

What is a laboratory liquid dispenser and how is it used in weighing?

What is the range of an analytical balance?

How can I quickly identify the capacity of an analytical balance?

What does the C mean in the analytical balance model name XPR226CDR?

What is the maximum and minimum load that can be weighed on an analytical balance?

What is the analytical balance bubble, and what is it used for?

Where can I find the level bubble on my analytical balance?

What types of analytical balances are available?

How is an analytical balance different from a precision balance?

What are the types of balances available?

What is the scale division (d) and the verification scale division (e)?

How can I weigh small samples on my analytical balance?

How accurate is an analytical balance?

What is the performance of an analytical balance?

What is an approved balance? When do I need a legal for trade balance?

Is my analytical balance legal for trade?

How are analytical balances made?

What is the most used analytical balance?

Why do I need to level an analytical balance?

How do I level an analytical balance?

How to use my analytical balance in a sustainable way?

What is the best analytical balance?

What does the DU mean in the XPR Analytical Balance names (example: XPR205DU)?

What does DR mean in the XPR Analytical Balance names (example: XPR205DR)?

What does the H mean in XPR Analytical Balance names (example: XPR106DUH)?

What does the Q mean in the XPR Analytical Balance names (example: XPR106DUHQ)?

What do the numbers mean in the XPR Analytical Balance names?

What does the name XPR stand for in the analytical balance?

What are the different analytical balance levels offered by METTLER TOLEDO?

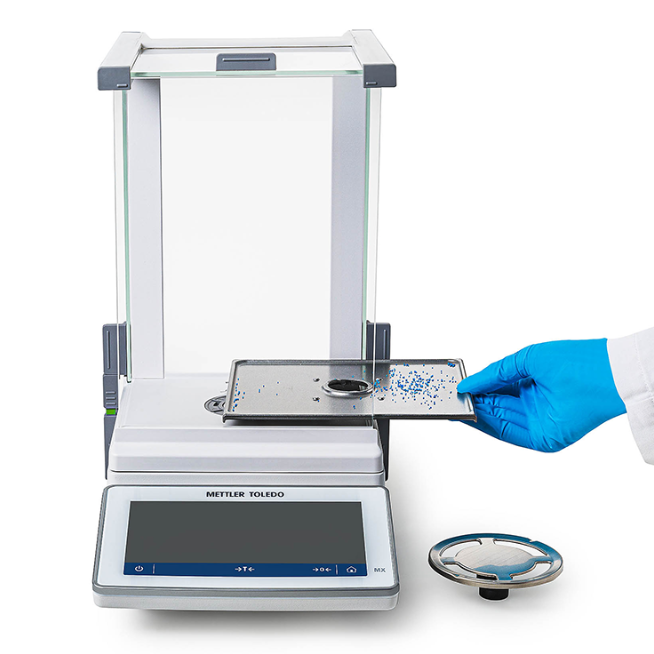

What are the best features of the MX Analytical balance line?

What size is an analytical balance?

What does /M mean in an analytical balance model name?

What is the purpose of draft shields in analytical balances?

What features and accessories are available on XPR Analytical balances to mitigate the effects of static electricity?

What is the importance of routine testing for analytical balances?

How do I know my balance's performance complies with USP General Chapter 41?

To know if your balance's performance complies with USP Chapter 41, the concepts of smallest net weight, minimum weight, and safety factor are key. The smallest net weight is the actual amount of sample that you intend to weigh. The minimum weight is the lowest amount of sample your balance can reliably measure while maintaining the required accuracy. The safety factor is the ratio between the smallest net weight and the minimum weight, providing a margin of reliability to account for changes in the balance performance between performance verifications. USP Chapter 1251 recommends maintaining an appropriate safety factor (typically 2 for stable laboratory conditions and trained operators) to ensure weighing accuracy. By verifying that your balance achieves a minimum weight with an acceptable safety factor relative to your smallest net weight, and by performing regular calibrations and performance checks, you can confirm compliance with USP Chapter 41 regulations. The MT GWP® Verification service and the ACC calibration certificate help you determine and ensure that all your balances are reliable enough during routine operation.

How do I choose the right safety factor for my analytical balance to meet USP General Chapter 41 requirements?

The choice of safety factor for your analytical balance depends on your laboratory conditions and weighing process. USP Chapter 1251 recommends a safety factor of 2 for stable laboratory environments with trained operators, and a safety factor of 1.5 for automated weighing procedures where environmental and operator influences are minimized. Monitoring and adjusting the safety factor over time helps maintain compliance and balance performance.

What performance checks should I do between calibrations according to USP General Chapter 41?

Periodic performance checks of analytical balances, including repeatability and accuracy tests, must be conducted between calibrations at risk-based frequencies. It is recommended to use a test load up to 5 % of the capacity for repeatability testing, and for multiple range analytical balances, additional repeatability tests are necessary for the coarse ranges used. These checks help maintain a consistent balance between performance and compliance. The MT GWP® Verification service and the ACC calibration certificate help you determine and ensure that all your balances are reliable enough during routine operation.

What are the key features of METTLER TOLEDO analytical balances that ensure precise and reliable weighing results?

METTLER TOLEDO analytical balances are designed with precision and reliability at their core. Key features include ultrasensitive weighing sensors that detect minute weight changes with high accuracy, advanced draft shields that minimize environmental disturbances, and intuitive touchscreen interfaces for easy operation. These balances also offer automated internal calibration and SmartGrid weighing pans to enhance stability and repeatability. Their robust construction and innovative weighing technologies ensure consistent, precise results, making them ideal for demanding laboratory applications.

How do I maintain and calibrate my METTLER TOLEDO analytical balance for optimal performance and accuracy?

To maintain and calibrate your METTLER TOLEDO analytical balance for optimal performance and accuracy, regularly clean the weighing pan and draft shield to prevent dust and residue buildup. Use appropriate weighing techniques, such as avoiding vibrations and drafts, and ensure that the balance is placed on a stable, level surface. Perform routine calibration using the balance's built-in internal calibration feature or external calibration weights according to the manufacturer's guidelines. Additionally, schedule periodic professional service and recalibration to comply with quality standards. Following these practices helps ensure precise measurements and extends the lifespan of your analytical balance.

- 1 mg Analytical Balances

- 200g Analytical Balance

- 4-Digit Analytical Balances

- 5-Digit Analytical Balances

- Analytical Balance 0.0001 g

- Analytical Balance 0.0001 mg

- Analytical Balance 0.001 mg

- Analytical Balance 0.01 mg

- Analytical Balances for Academic Use

- Analytical Balances for Chemical Analysis

- Analytical Balances for Multiple Users

- Analytical Balances for Pharmaceuticals

- Analytical Balances for Research and Development

- Analytical Balances with a Touch Screen

- Analytical Balances with Bluetooth Connectivity

- Analytical Balances with Compliance Reporting

- Analytical Balances with Touchless Sensors

- Analytical Lab Balance

- Balances with a High-Resolution Display

- Compact Analytical Balances

- Digital Analytical Balance

- Dual-Range Capability Analytical Balances

- Electronic Analytical Balances

- High Precision Analytical Balances

- Semi Micro Balances

- Uncertainty of Analytical Balance

- XPR Automatic Balance

- XPR Essential Analytical Balances