SimpleCheck Standards

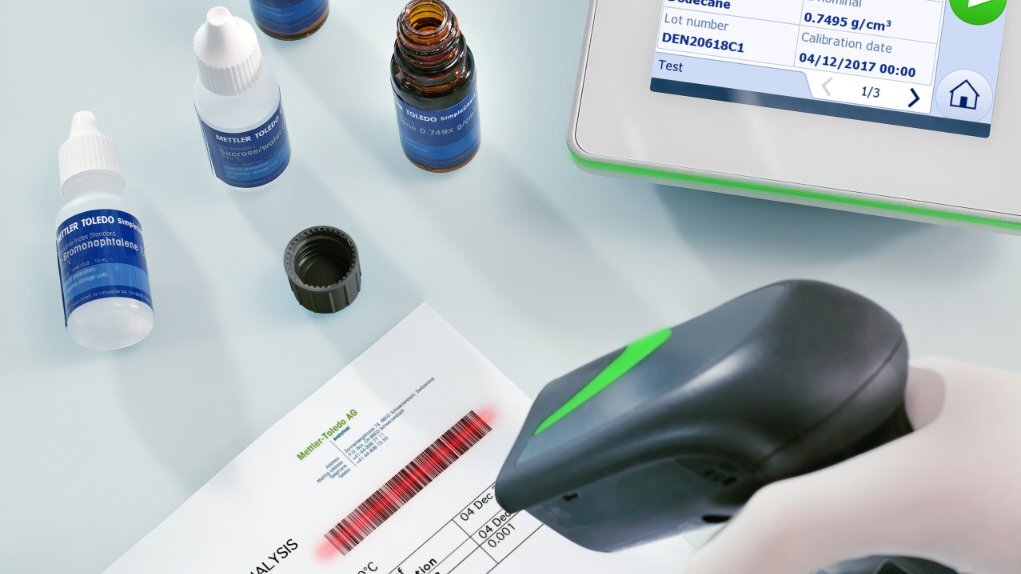

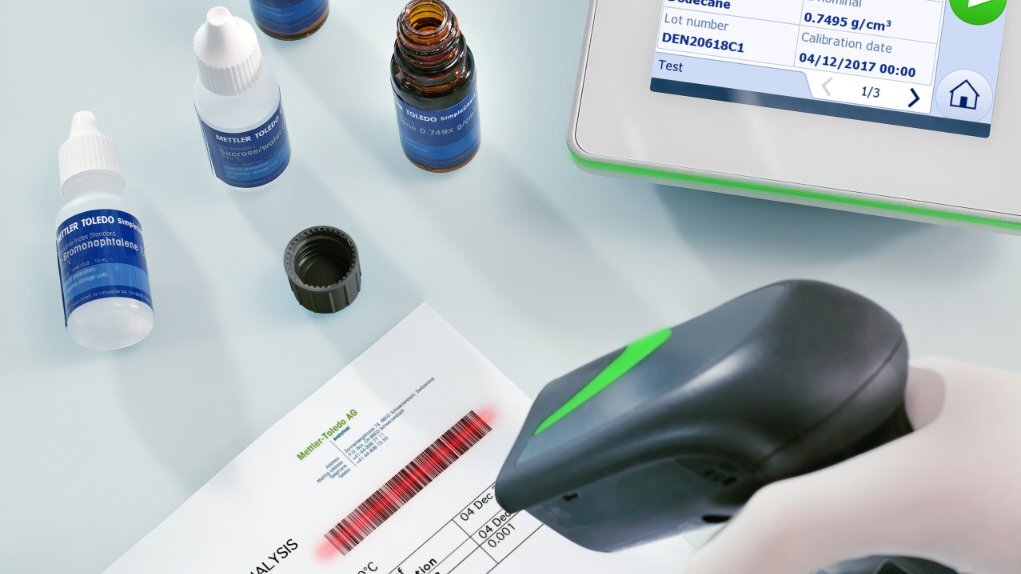

SimpleCheck™ standards enable fast and reliable performance verification for EasyPlus™ density meters and refactometers thanks to the built-in user guidance.

It is crucial to ensure compliance and optimal functionality of your density meter and refractometer amid today’s demanding regulatory landscape.

At METTLER TOLEDO, our dedicated service team combines deep expertise with a thorough understanding of diverse market regulations to support your equipment throughout their lifecycle. From installation and qualification to calibration and maintenance, we help you meet stringent compliance standards across various industries, enabling reliable, precise results you can trust.

To ensure that the measurement cell of your density meter or refractometer is clean and free from sample residuals from previous measurements, a basic check with deionized water is sufficient during routine operation. But what if your quality management system demands higher standards for traceability and regulatory compliance?

Our preventive maintenance and calibration services encompass comprehensive performance verification and certification, utilizing certified reference standards to ensure complete traceability. The same standards can be used for your own, more frequent performance verification.

SimpleCheck™ standards enable fast and reliable performance verification for EasyPlus™ density meters and refactometers thanks to the built-in user guidance.

For Excellence Density Meters and Refactometers we offer combined certified reference standards covering a wide measurement range.

Did you know that accurate temperature control is indispensable for correct density measurements? Or that a small air bubble of ~1 mm diameter in the sample can cause an error of about 0.000052 g/cm3 in density measurements?

Or did you know that insufficient cleaning of the prism of your refractometer can drastically falsify refractive index measurements?

Discover effective strategies to enhance your routine density and refractive index measurements with our comprehensive measurement guides. For example, learn how to clean the measurement cells, how to prevent sampling errors, how to automate your workflow and more.

These useful tips and best practices will help you achieve more accurate and reliable measurement results every time.

The following tasks are executed during preventive maintenance:

Yes, we offer preventive maintenance for our sample changers and InMotion™ autosamplers. The service includes thorough visual inspection and cleaning, functional and operational testing, and adjustments, if required.

Signs that indicate your density meter or refractometer requires maintenance or repair include:

Regular performance verification and calibration can help to identify possible issues early. If you notice any of these signs, it’s advisable to consult a professional service.