Accurate and reliable inspection and quality control

Our metal detection systems for the food industry are designed to accurately detect metal contaminants in food and reject them from the production line, providing a reliable method of protecting both customer and brand. These systems can assist with food production quality control procedures and help with meeting metal detector standards.

Minimal product waste

Metal detection systems from METTLER TOLEDO not only support compliance with metal detection standards, but they also help minimize wasted product. When metal contamination is identified by our systems, they efficiently reject just the contaminated product without wasting large amounts of good product, protecting your bottom line.

Finding optimal spherical sensitivity

By achieving the right spherical sensitivity for inspecting your specific food type, it improves the accuracy of detection and and removal of ferrous and non-ferrous metal contaminants, including the difficult-to-detect non-magnetic stainless steel. To help increase the chances of reaching optimal sensitivity, you should choose the type of metal detection system that is designed for your specific food application.

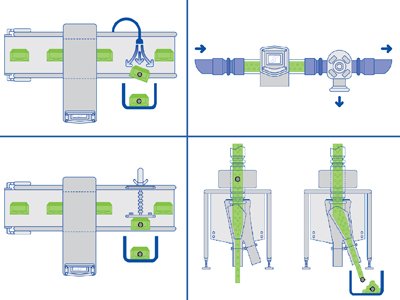

A variety of high-performance metal detectors

We offer a wide product range of metal detectors that can help support reaching metal detection standards in the food industry for different phases of production.

For instance, this can include throat metal detectors and gravity fall metal detectors for free-falling applications, as well as conveyor and tunnel metal detectors for a range of food applications, and pipeline metal detection systems which are ideal for liquid or paste applications.