TDL gas analyzers are used in a wide range of applications across a variety of industries. Installations are common in bulk and fine chemical industries, refining, petrochemicals, polymers, mining and metals processing, pharmaceutical manufacturing, and food and beverage production.

GPro 500 sets the industry standard for oxygen measurement performance for safety applications and explosion prevention.

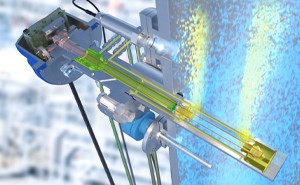

Only the GPro 500 Wafer Cell adaption provides in situ oxygen measurement in the tightest installation spaces and smallest pipes such as DN50, DN80 and DN100 (2”, 3” and 4” diameters).

In industries such as chlor-alkali, TDL analyzers by METTLER TOLEDO can replace traditional measurement systems for moisture monitoring to prevent compression system corrosion.

A GPro 500 with a filter probe adaption is optimal for combustion applications where high dust loads could typically obstruct measurement. This setup is particularly appropriate for fired heaters and boilers.

In inerting and blanketing applications for chemical storage tanks or reactors, the use of a non-purge probe reduces running costs without compromising safety.