The sample racks of the METTLER TOLEDO Autosampler can be adapted to individual customer requirements.

Figure 3. The sample racks of the METTLER TOLEDO Autosampler can be adapted to individual customer requirements.

METTLER TOLEDO has expanded its automation offering for UV/Vis spectroscopy, making laboratory workflows more efficient and reliable. The InMotion autosampler independently feeds samples to the UV/Vis spectrophotometer, reducing manual handling while supporting reproducibility and safety.

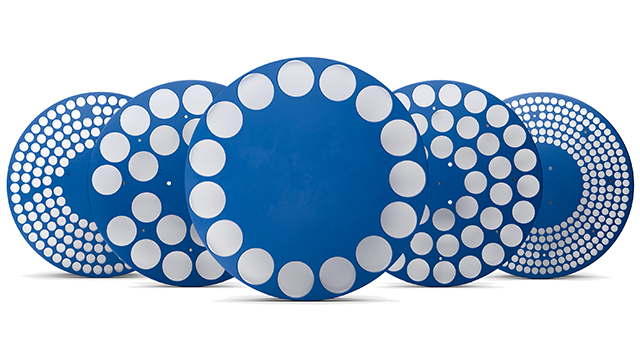

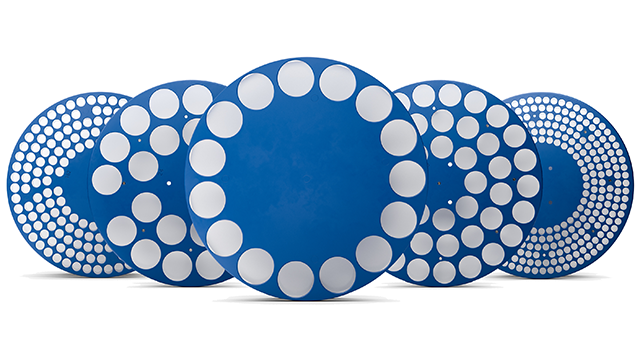

Standardized racks for 25 to 100 milliliter volumes are available, but what makes the system unique is the ability to design custom racks for specific customer requirements. This flexibility makes InMotion an unrivaled solution for laboratories in the chemical and beverage industries, where high sample volumes are the norm.

Figure. 1. Customized Racks and Expert Support for Efficient Laboratory Workflows.

The InMotion autosampler stands out for its modularity. Standard racks handle volumes between 25 and 100 mL, making it ideal for extensive material analysis. At the same time, individualized racks can be developed to fit specialized workflows.

UV/Vis spectrophotometers connect to InMotion easily via immersion probes or flow cells, allowing the system to become part of a larger portfolio of instruments that METTLER TOLEDO offers for safe, efficient automation of analytical processes.

Figure 2. Start small, then scale as your workload grows. Select racks holding 18, 27, 34, 50, 55, 69, 113, 182, or 303 samples with 25 mL, 80 mL, or 100 mL vessels. Each base: Flex, Pro, Max, uses its own matched rack family, and a Pro base can be field-upgraded to Max, securing future capacity without changing autosamplers.

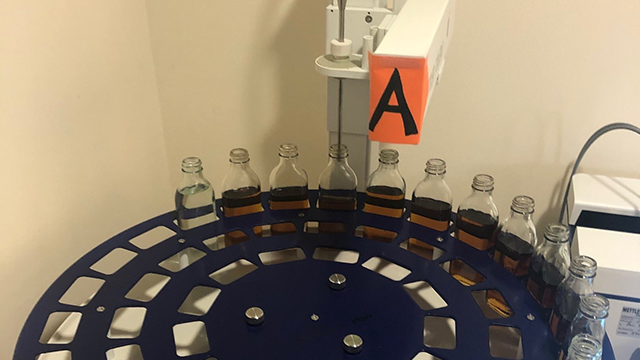

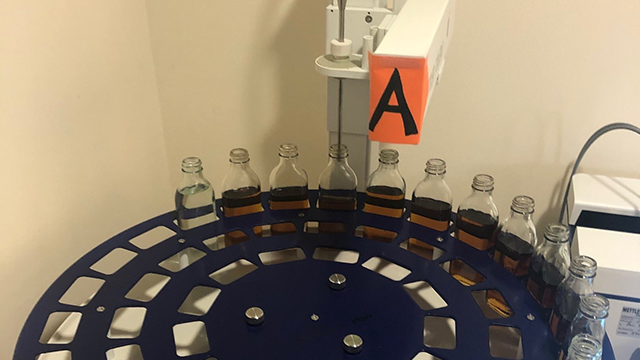

The sample racks of the METTLER TOLEDO Autosampler can be adapted to individual customer requirements.

Figure 3. The sample racks of the METTLER TOLEDO Autosampler can be adapted to individual customer requirements.

METTLER TOLEDO emphasizes that the biggest efficiency gains come when automation is tailored to the laboratory’s needs. To make the transition straightforward, check out our latest resources:

Both resources offer clear, comprehensible insights that are valuable even for facilities not yet using METTLER TOLEDO instruments.

For labs that want to move further, we also provide personalized consulting to design and implement tailored solutions. This ensures every lab, whether new to automation or looking to expand, can benefit from efficient, reliable UV/Vis processes.

With the addition of InMotion autosamplers, METTLER TOLEDO strengthens its UV/Vis automation portfolio, focusing on larger sample volumes and customer-specific adaptations. The system enables laboratories to:

This combination of technical flexibility and knowledge-driven support ensures laboratories are guided step by step toward efficient, reproducible spectroscopic automation.

Anika Adams is Product Manager for UV/Vis Spectrophotometers at METTLER TOLEDO, where she focuses on driving innovation and optimizing customer workflows.

With a degree in business administration and experience spanning software development, mechanical engineering, and production, Anika brings a multidisciplinary perspective to the laboratory business. Her expertise lies in automating and enhancing customer processes, ensuring both product excellence and customer satisfaction.