Figure 2. Mr. Kunz, the Quality Assurance Manager at RAMSEIER Suisse AG, and the measurement system comprising an InMotion™ Flex Autosampler, DM40 density meter, RX50 refractive index cell, and T90 titrator.

In today’s competitive beverage market, speed, reliability, and compliance in quality control are non-negotiable. Producers must consistently deliver products that meet strict standards, while keeping up with high throughput demands. For RAMSEIER Suisse AG, a leading Swiss beverage producer, automation has been the key to overcoming these challenges. By adopting METTLER TOLEDO’s multiparameter system with the InMotion™ Autosampler, Ramseier reduced analysis time by up to 10 minutes per sample while ensuring repeatable, high-quality results.

Figure 1. Combining a refractometer and a titrator in an automated multiparameter system with a sample automation unit and PC software allows to measure Brix, pH and acidity and calculate the acid corrected Brix and ratio fully automatically.

Ramseier has decades of experience in beverage production, with popular brands like RAMSEIER, SINALCO, and ELMER. Their extensive product portfolio requires rigorous QC testing, including measurements of density, sugar content (Brix), acidity, pH, and CO₂ content.

Previously, this meant:

The result was high workloads for lab technicians, especially after weekends when backlogs of samples accumulated.

Ramseier turned to METTLER TOLEDO for a smarter approach. The answer was a fully integrated multiparameter analysis system combining:

This setup enabled direct degassing within the sample beaker using an optimized stirring method and air pump. The automated process not only saved time but also eliminated operator dependency. Depending on the sample, the titration endpoint is either pH 7.0 or 8.1, and depending on the type of acid to be determined, different factors are used in the acidity calculation.

Figure 2. Mr. Kunz, the Quality Assurance Manager at RAMSEIER Suisse AG, and the measurement system comprising an InMotion™ Flex Autosampler, DM40 density meter, RX50 refractive index cell, and T90 titrator.

With automation, analysis is reduced to just a few operator steps:

The system then performs all measurements in a single run:

During analysis, a 5 mL sample loop is used to transfer the sample. While density and refractive index are measured, the valve automatically switches and pumps the loop contents with deionized water into the titration beaker for acidity measurement. This ensures seamless integration of all parameters in a single run.

After each measurement series, the system can be flushed and filled with deionized water at the push of a button. An optional cleanliness test for the density and refractometer cells can also be integrated, ensuring reliable results across batches.

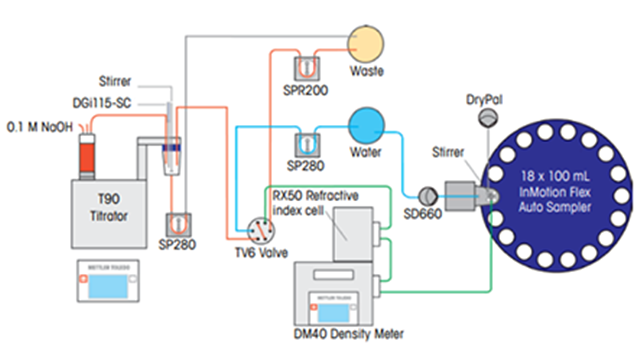

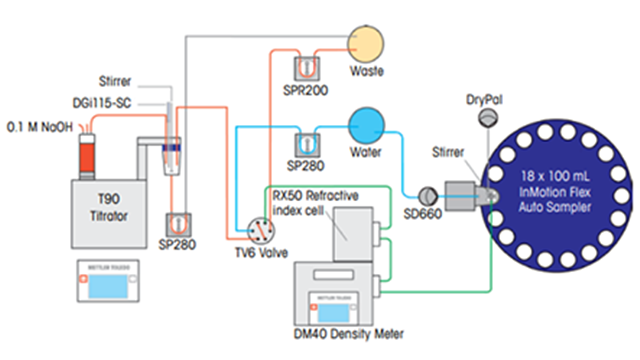

Figure 3: Schematic diagram of the automated measuring system.

As Mr. Kunz, Quality Assurance Manager at Ramseier, puts it:

“With the fully automatic combined analysis, we have saved at least 10 minutes per sample, and results are highly repeatable.”

The system’s modular design means beverage producers can tailor it to their specific needs, whether measuring just Brix and pH or adding more advanced parameters. With LabX™ integration, all results are securely managed and audit-ready.

For Ramseier, automation has meant more than time savings, it has created a sustainable, reliable, and efficient QC process that supports their reputation for quality beverages.

Discover how METTLER TOLEDO’s multiparameter analytical systems simplify complex workflows. In this example, water samples are automatically analyzed for pH, conductivity, alkalinity, color, and turbidity, with measurements seamlessly transferred between a titrator and a UV/Vis spectrophotometer, all without operator interference.

Just as at RAMSEIER, automation enables faster, more reproducible, and more efficient workflows across industries.

Explore the full InMotion™ product page and learn how your lab can benefit from smarter automation.

Anika Adams is Product Manager for UV/Vis Spectrophotometers at METTLER TOLEDO, where she focuses on driving innovation and optimizing customer workflows.

With a degree in business administration and experience spanning software development, mechanical engineering, and production, Anika brings a multidisciplinary perspective to the laboratory business. Her expertise lies in automating and enhancing customer processes, ensuring both product excellence and customer satisfaction.