Calibration and Adjustment for Thermal Analysis

Enhance Your Understanding and Ensure the Accurate Performance of Your Instruments

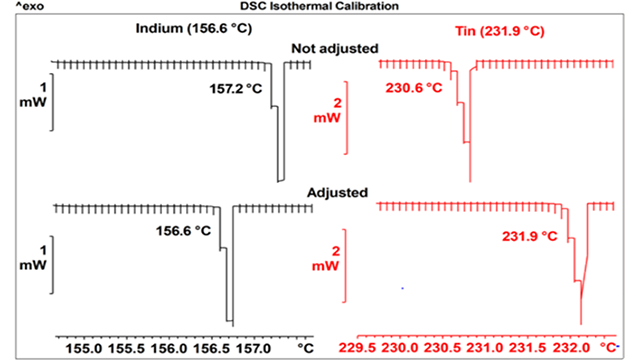

Calibration of an instrument involves comparing a measured value with that of a reference substance of known accuracy. Adjustment corrects any deviations by realigning the instrument’s output with a known standard.

Why calibration and adjustment matter

Correct calibration and adjustment procedures are essential for ensuring instrument accuracy and precision. They enable reproducible results and confident decision-making in both research and industrial applications.

Download our comprehensive calibration handbook to access expert insights and best practices designed to keep your thermal analysis equipment performing at its peak. Discover proven calibration methods that will help you achieve accuracy, reliability, and consistency in every measurement.

What You Will Find in the Handbook

Basic Principles and Procedures: Refresh your expertise with an overview of calibration and adjustment procedures. Understand which thermal analysis parameters should be calibrated.

Low Temperature Calibration: Discover the importance of performing low-temperature calibrations.

High Pressure DSC Calibration: Find out how temperature adjustments are affected by pressure.

TGA Calibration Using Curie Temperature: Learn how to perform TGA temperature calibration and adjustment using magnetic transition (Curie point) standards.

Minimum Sample Weight: Read our tips for preventing errors during the determination of initial sample mass.

Isothermal Calibration and Adjustment: Find out when you should perform isothermal adjustments.

Influence of Sample Volume: Understand why you should calibrate and adjust your instrument using a sample volume close to that of the samples being measured.

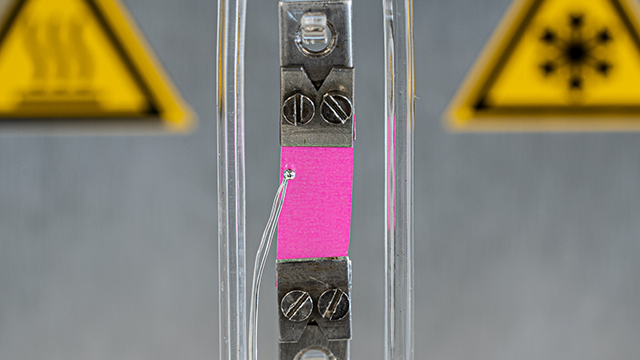

TMA and DMA Calibrations in Tension Mode: For instruments that perform measurements in tension mode.

Unique Calibration and Adjustment Features in the STARe Software:

- FlexCal™ reduces adjustment time by applying known adjustment parameters for each combination of module, crucible, and gas type.

- Patented, electrical heat flow adjustment saves time, improves accuracy over the entire temperature range, and removes operator influence.