Due to the complexity and expense of semiconductor production, reliable, specialized equipment and strict adherence to process tolerances are essential from raw material intake to final packaging. Explore the topics below to see how our equipment can enhance your operations, and download the case study collection for further details.

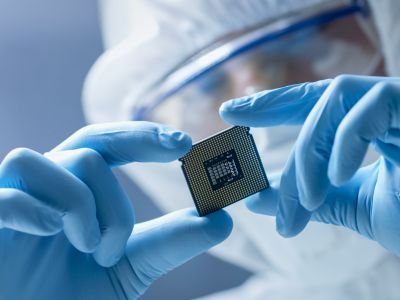

Semiconductors are key components in the electronics industry. Their production requires robust, accurate, and safe weighing technology to precisely manufacture silicon wafers and to monitor the dispensing process accurately during integrated circuit (IC) packaging.

Read the case study to learn about our solutions designed for automation, which have become indispensable tools for manufacturers across the semiconductor value chain, enabling the seamless and fast production of high-quality chips.

|

Enhancing Production Efficiency in Manufacturing

Dispensing Accuracy: Meeting Typhoons Head-On

An IC packaging vendor in a coastal city faced production disruptions during typhoons and earthquakes. After upgrading to a high-precision weigh module with a built-in typhoon filter, they maximized production capacity with year-round accurate dispensing.

Precision Slurry Production: Enabling High-Quality Wafers

A leading semiconductor chip producer sought higher precision in chemical-mechanical polishing (CMP). By integrating high-precision PBK9-APW bench scales into their automated slurry formulation process, they achieved ambitious precision targets.

Semiconductor Chemicals: The Right Mix

A semiconductor chemicals manufacturer needed to prove the accuracy of its multi-vendor tank-weighing system. They implemented an automated solution with performance assurance and a new calibration method to eliminate production delays and disposal costs.

Slurry-Delivery Equipment: Smart Weighing

Abrasive particle distribution in CMP slurry is crucial for material removal rates, making precise ingredient weighing vital. The C6 PowerMount™ weigh module and IND360 weighing indicator provide accurate mixing control with 50 g readability.

Semiconductor Gas Bottling: Hazardous Area Performance

A bottled gas supplier was facing difficulty finding an integrated weighing and automation solution that could meet both their stringent accuracy requirements and their safety needs. METTLER TOLEDO and Rockwell Automation turned out to be the winning combination, providing a seamless solution that helped them solve a nearly insurmountable problem.

Professional Services to Deliver a Full Solution

We provide the services that meet the demands of your customers and help with system readiness, deliver quality assurance, and offer:

- Complete system qualification

- Installation

- Setup

- Calibration

- Documentation

- And more!

Our products and services maximize the value you offer, with factory-trained technicians located in over 100 countries to provide support anywhere in the world. Learn more about our service offerings.