METTLER TOLEDO XPR microbalances offer unique accuracy and exceptionally low minimum weights. The weighing method, including target weight, tolerances, and number of samples can be saved on the balance and accessed directly from a shortcut on the balance display. Built-in quality assurance functions ensure weighing results meet defined tolerances and standards.

Meet accuracy requirements

METTLER TOLEDO microbalances have USP minimum weight values as low as 0.82 mg with a readability of 0.001 mg enabling you to easily meet the accuracy requirements of CHNS(O) elemental analyses. Built-in quality assurance features such as StatusLight™, LevelControl and GWP Approved help ensure right-first-time results.

Eliminate manual transcription

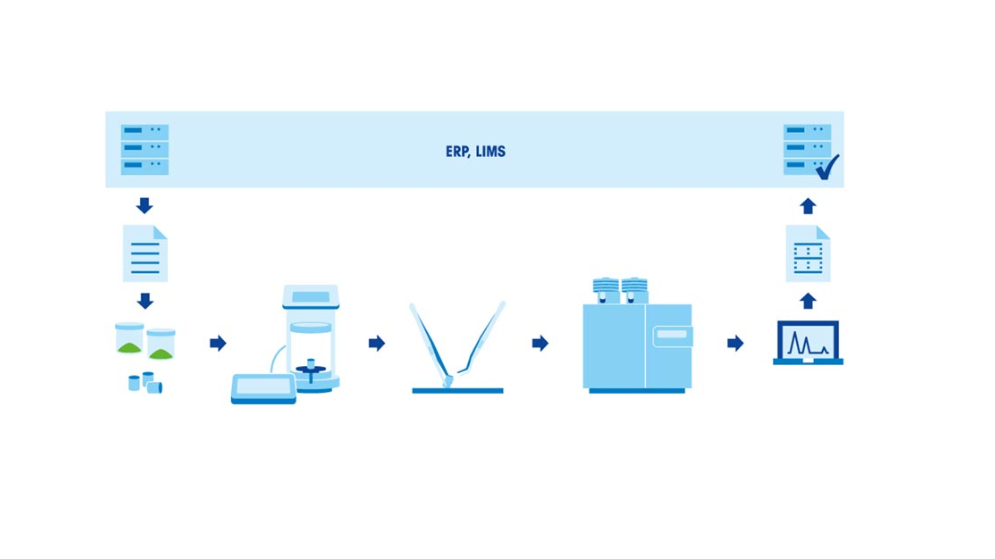

Each weight result is saved on the built-in results notepad so there is no need to write results down by hand. The results can be printed out or transferred via multiple connectivity options to a USB stick, PC or another analytical instrument. This eliminates transcription errors and saves a significant amount of time.

Fast and stable performance

The Active Temperature Control (ATC) feature ensures stable balance performance, delivering results considerably faster than a standard microbalance. Automated draft shield doors help to maintain balance stability and make weighing processes faster and more ergonomic.

Space-saving solutions

The compact footprint saves space, which is especially important when working in a fume cupboard. In addition, the secondary SmartView terminal above the weighing chamber has all the basic functions you need as you weigh-in, while the main terminal can be placed wherever is most convenient — even outside the fume cupboard.