Accurate offline analysis of particle and droplet systems depends on the successful removal and preparation of a representative sample from the process stream. This procedure is often complex, as most offline techniques impose strict constraints on the measurable range of particle concentration, size, and shape.

Sample preparation can be a labor-intensive and expensive multi-step process, potentially introducing errors that affect the final particle size distribution data. Common preparation methods, such as filtration, drying, subsampling, redispersion, and dilution, must be carefully controlled to prevent modifications to the sample.

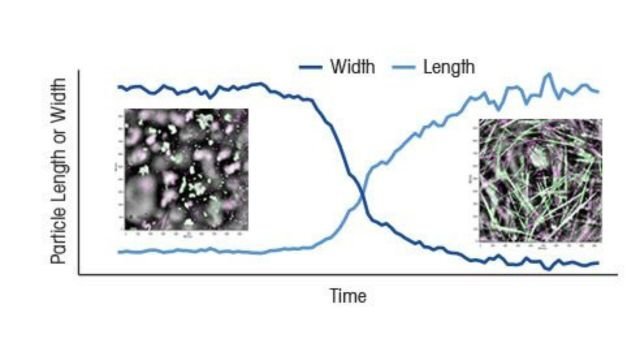

Altered Sample Shape/Size Due to Changed Particle Environment

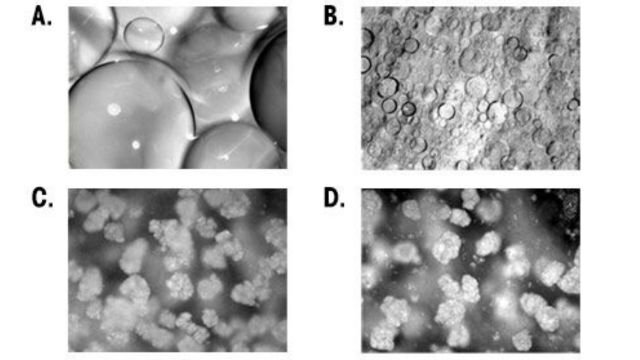

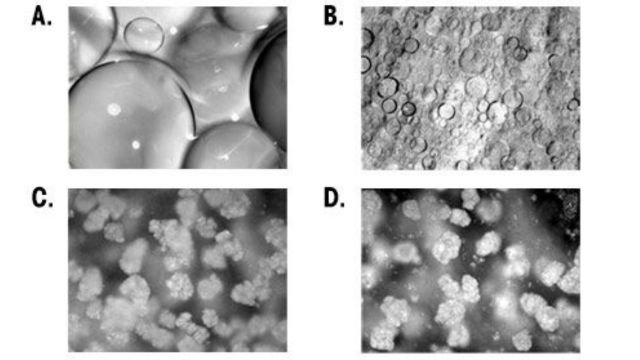

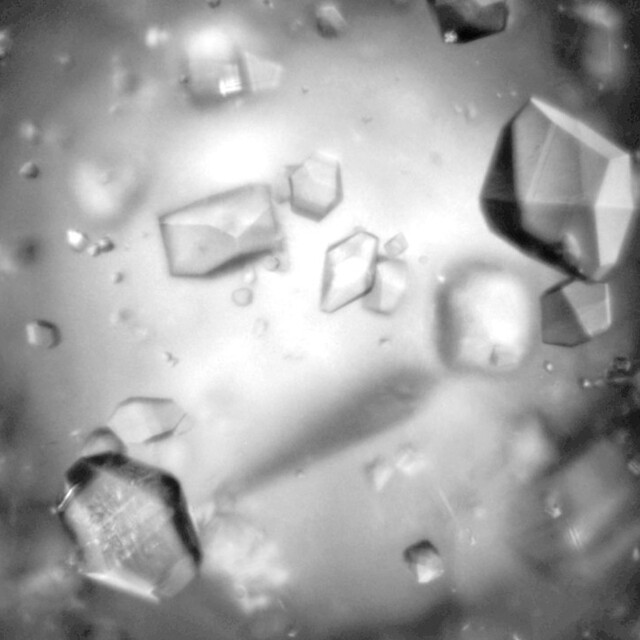

These sample preparation steps may significantly alter the particles or droplets of interest. Even with the utmost care and precision in the sampling and sample preparation methods, the actual particles that are analyzed may be significantly different from the particles that were initially present in the process vessel. For example, mannitol crystals image taken by real-time microscopy (Figure A) is significantly different from that taken by a standard offline light microscope (Figure B). Sampling and preparation for offline microscope analysis have resulted in significant breakage and delicate dendritic structures observed in process go undetected.

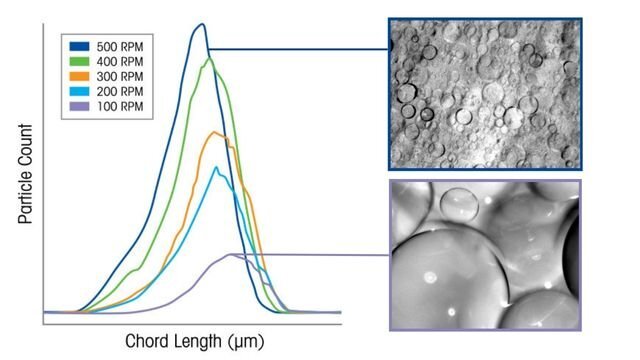

Assuming Spherical Shape

The particle size of non-spherical particles is often reported using an equivalent diameter. For example, in the right figures, particles with different shapes but equivalent volumes are depicted. If particle size is reported based on volume, the spherical sample and the needle-shaped sample are identical. However, the behavior and throughput of sieving the two samples might be quite different, because their sieve diameters and shapes are far from identical. Therefore, care should be taken to determine how shape influences particle size analysis results, and if possible to determine particle shape using a technique, such as EasyViewer imaging.

Effects of Time Delay

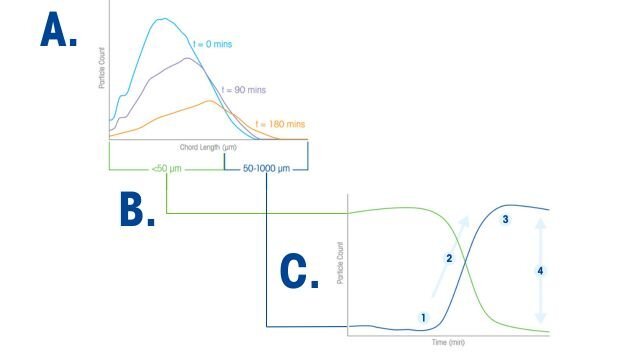

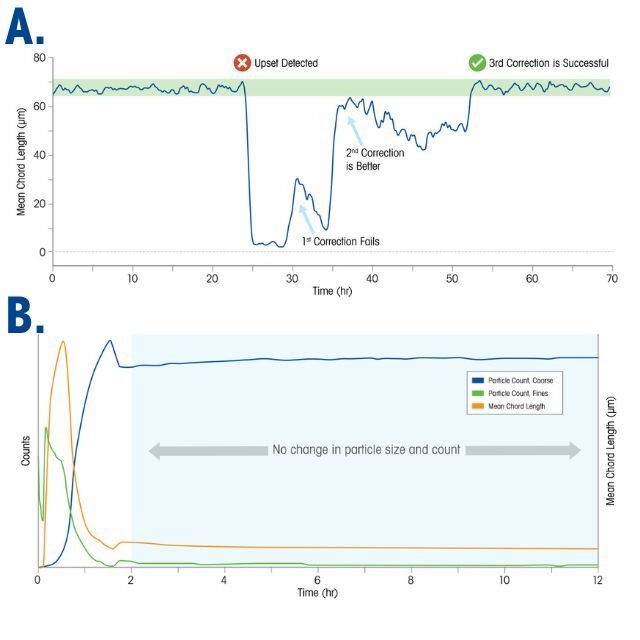

Since most particle process streams operate at a solids loading much higher than anything traditional particle size analyzers can handle, careful and time consuming sample preparation is needed for the measurement. The measurement and analysis takes time as well, from minimum minutes (e.g. by light scattering methods) to even longer (e.g. by sieving and offline microscopy).

In order to obtain continuous information, samples would have to be manually extracted frequently and analyzed on the fly. This approach may also impose unacceptable level of risk, especially for processes at elevated temperatures and pressures with toxic or explosive slurries and solvents. The inevitable time delay between sampling and the receipt of results with offline tools makes them difficult to implement for true real-time measurement, and makes them unsuitable for monitoring process continuously as it changes over time. Inline particle size analyzers are the recommended alternative.