Food Safety - Metal Detection

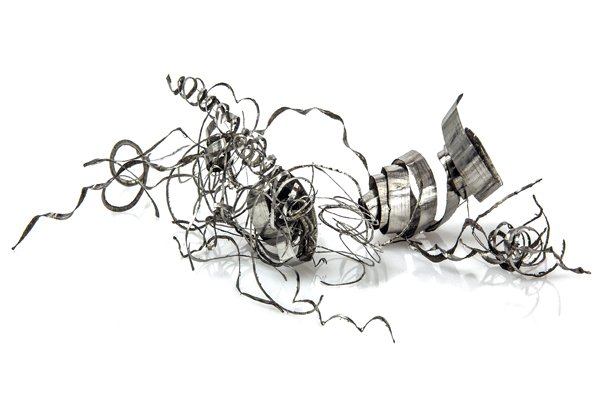

Metal contamination is a significant safety concern in the food industry and can occur at any stage—from raw material intake through processing and final packaging. Implementing robust metal detection systems is essential for food manufacturers to prevent metal contamination, uphold food industry compliance with metal detection standards, and demonstrate due diligence in protecting consumer safety.