Pipette Performance Matters - Trust Rainin Service to Deliver

Pipette Performance Matters - Trust Rainin Service to Deliver

FAQs

What does Rainin make?

Where are Rainin products made?

How many people work at Rainin?

Are Rainin instruments available globally?

How can I apply for jobs at Rainin?

How can I improve precision when pipetting small volumes of liquids with varying viscosities?

Liquids with differing viscosities can produce inconsistent results if they are all handled the same way. Adjust your aspiration and dispensing speeds according to the fluid’s thickness: pipette viscous liquids more slowly and always at an even pace.

Pre-wet the tips and consider using reverse pipetting to achieve more uniform delivery. Keep your pipette calibrated and your technique consistent.

Rainin pipettes, working in concert with our wide range of tip options, offer the adaptability and refined control required to handle a broad spectrum of fluid properties with high precision.

What's the best way to store a pipette?

Store pipettes vertically, hanging from a shelf or pipette stand. Keep pipettes clean and free of any contaminants. Keep pipette tip racks closed.

Why is accurate pipetting important?

Most life science applications include critical liquid handling steps where pipetted volume directly influences the result. If pipetting isn't consistent and accurate, then time, money, and material can go to waste. Accurate pipetting forms the foundation of reproducible work, which is essential to generating meaningful data.

For more information on proper pipetting technique and training offered by Rainin, visit the Good Pipetting Practice homepage.

How do I calibrate a pipette?

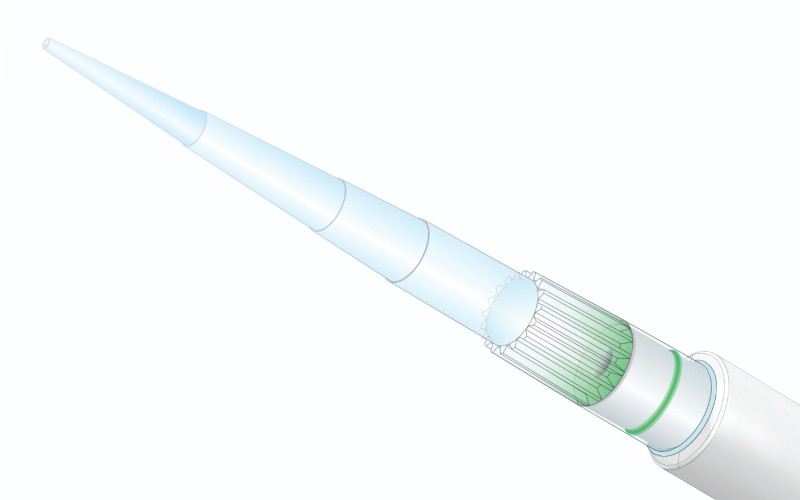

Calibration is the controlled and documented measurement of a pipette's systematic error rate (accuracy) and random error rate (precision). In many laboratory environments, pipette performance must be regularly tested and documented by law under specific conditions certified by an accredited body.

ISO-certified providers calibrate pipettes in a controlled setting. Results are securely documented on a calibration certificate, adding to an audit-ready performance history for each instrument. When adjustments are necessary, ISO-certified calibration labs provide expert service with manufacturer-recommended parts and lubricants.

Rainin and METTLER TOLEDO are the world's largest pipette service organization with quick turnaround from mail-in and onsite service options. Service labs are ISO 17025 certified, and procedures follow the 2022 update to ISO 8655.