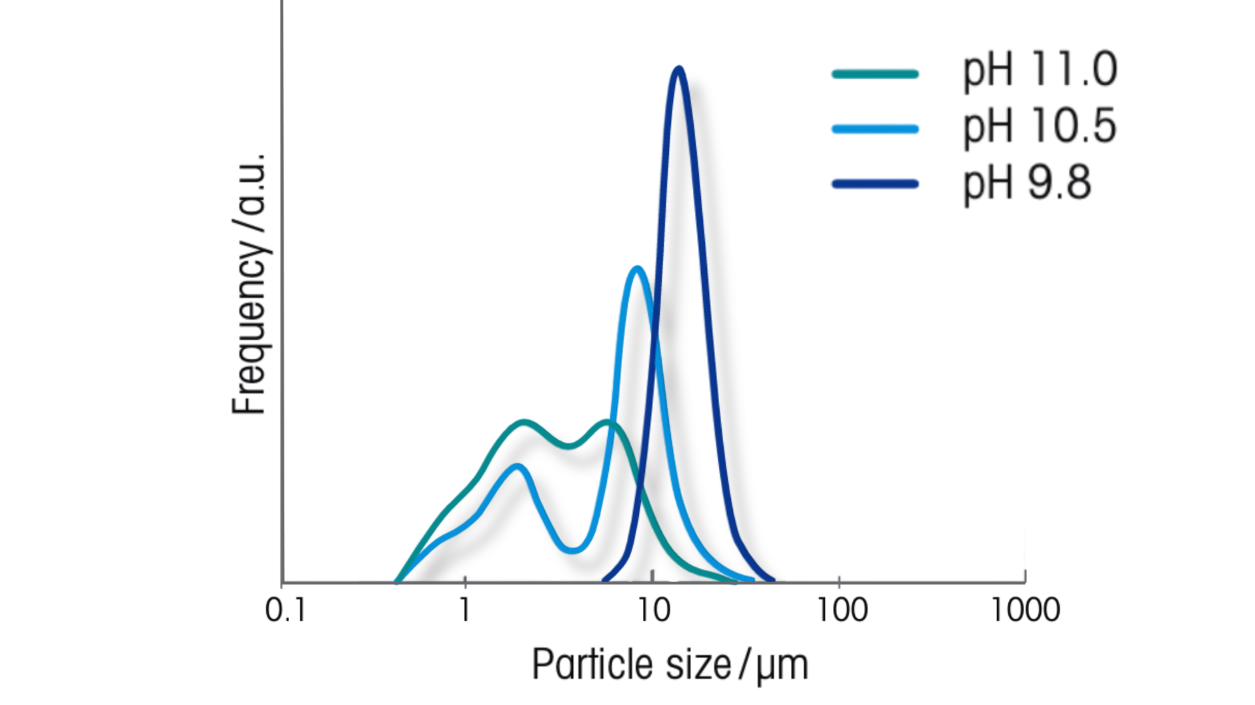

Maintaining very tight pH control during PCAM production is essential for achieving the specific particle sizes that ensure that the batteries, and ultimately the cars and devices we need, are efficient and reliable.

The figure (H. Muramatsu; D. Endo; T. Sasaki) shows how pH affects particle size distribution.