Polymerization Application Note

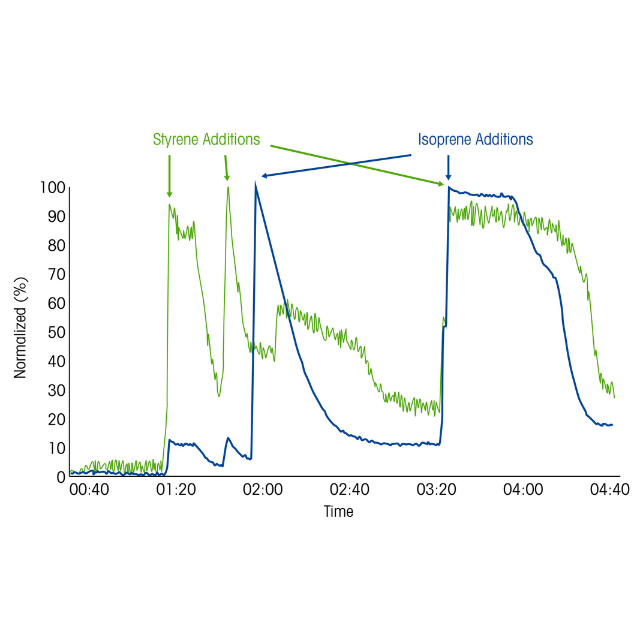

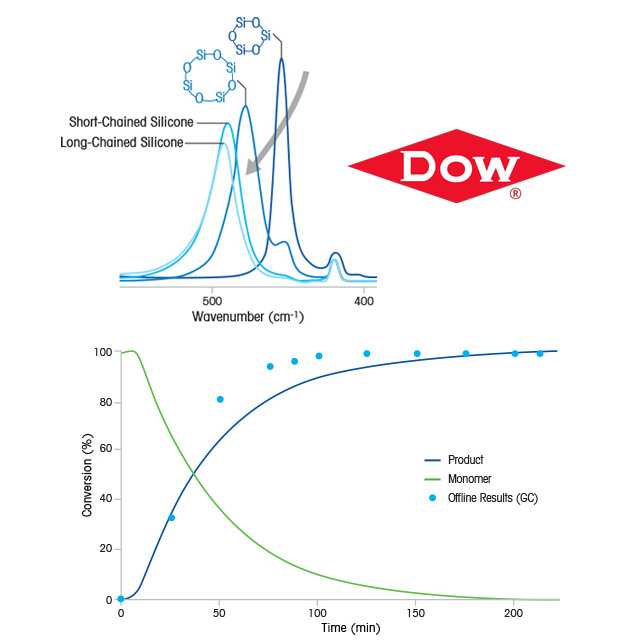

In-Situ Raman Affirms Target Chain Length is Achieved

For a wide range of industries, silicone's diverse properties enable companies to design products with specific, fit-for-purpose characteristics. These products exploit the varied properties of silicone rubbers such as strength, thermal resistivity, and stability. Typically, silicone is produced via hydrolysis of a chlorosilane followed by a terminal functional group addition, or through polycondensation of a cyclic siloxane. Each of these methods are equilibrium reactions that produce low-molecular-weight products with a wide range molecular weight distribution.

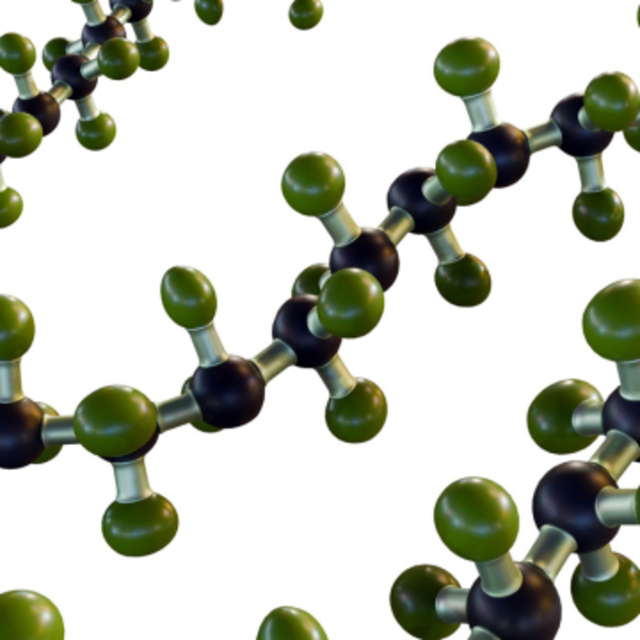

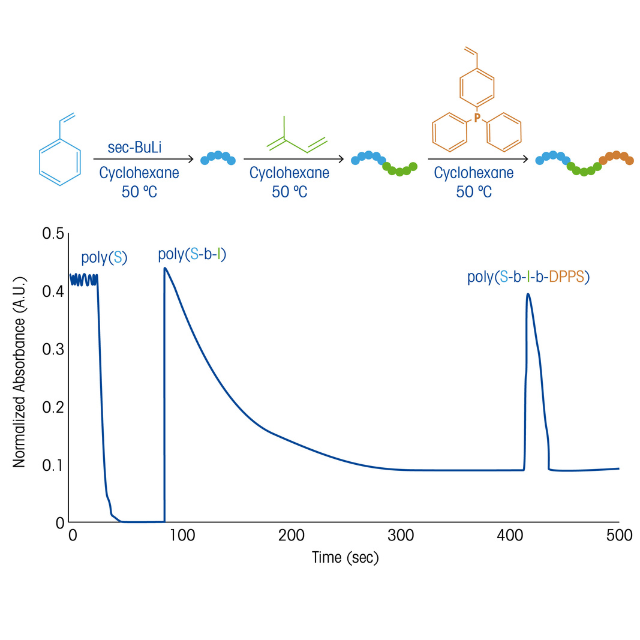

Dow researchers have developed an alternate means of producing silicone, based on a precisely controlled polymerization, to yield product with targeted, uniform chain lengths. In this synthesis, a lithium-based reactant serves to open a cyclic tri-siloxane ring, followed by addition of another cyclic siloxane reagent, to yield a monodispersed silicone polymer.

This novel silicone polymerization, which results in monodispersed product with precisely controlled chain lengths, is tracked by ReactRaman, eliminating the delays and reaction uncertainties associated with offline GC analysis. Reaction initiation, progress and kinetics are all readily measured by the Raman method, providing continuous, real time verification that the reaction is proceeding as expected.